The Process

How we produce

- Peeling the logs

- Scanning the logs

- Place the log in the software

- Cutting the logs

Peeling the logs

We peel the logs using high pressure water and a rotary nozzle. This alows us to maintain the natural shape of the logs. Other methods such as a draw knife, cut into the cambium layer of the wood requiring you to seal the logs after peeling.

Scanning the log

The log can be scanned with a speed of 1.5m/s and a precision of 0.02mm on a mesh of 3mm x 3mm

Cutting the log

This cut is done on an old big BZ machine. Today we cut with ABB robots on a precision of 0.07mm

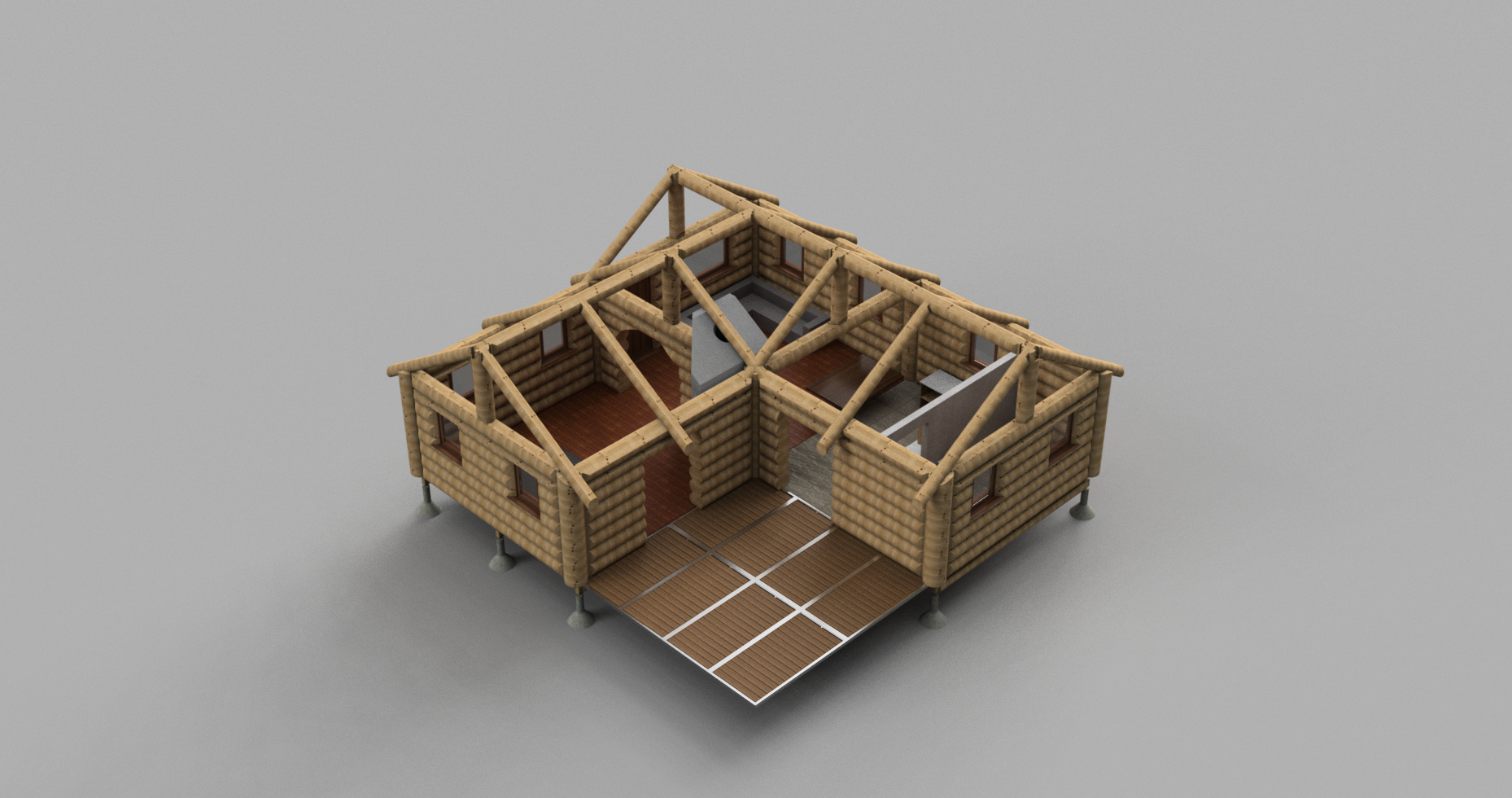

Result

Fit's perfect!!

The groove cuts are not optimized here. But you can see the space at the scribe-line for the P-Gaskets from John Boys ( www.logworks.ca ).

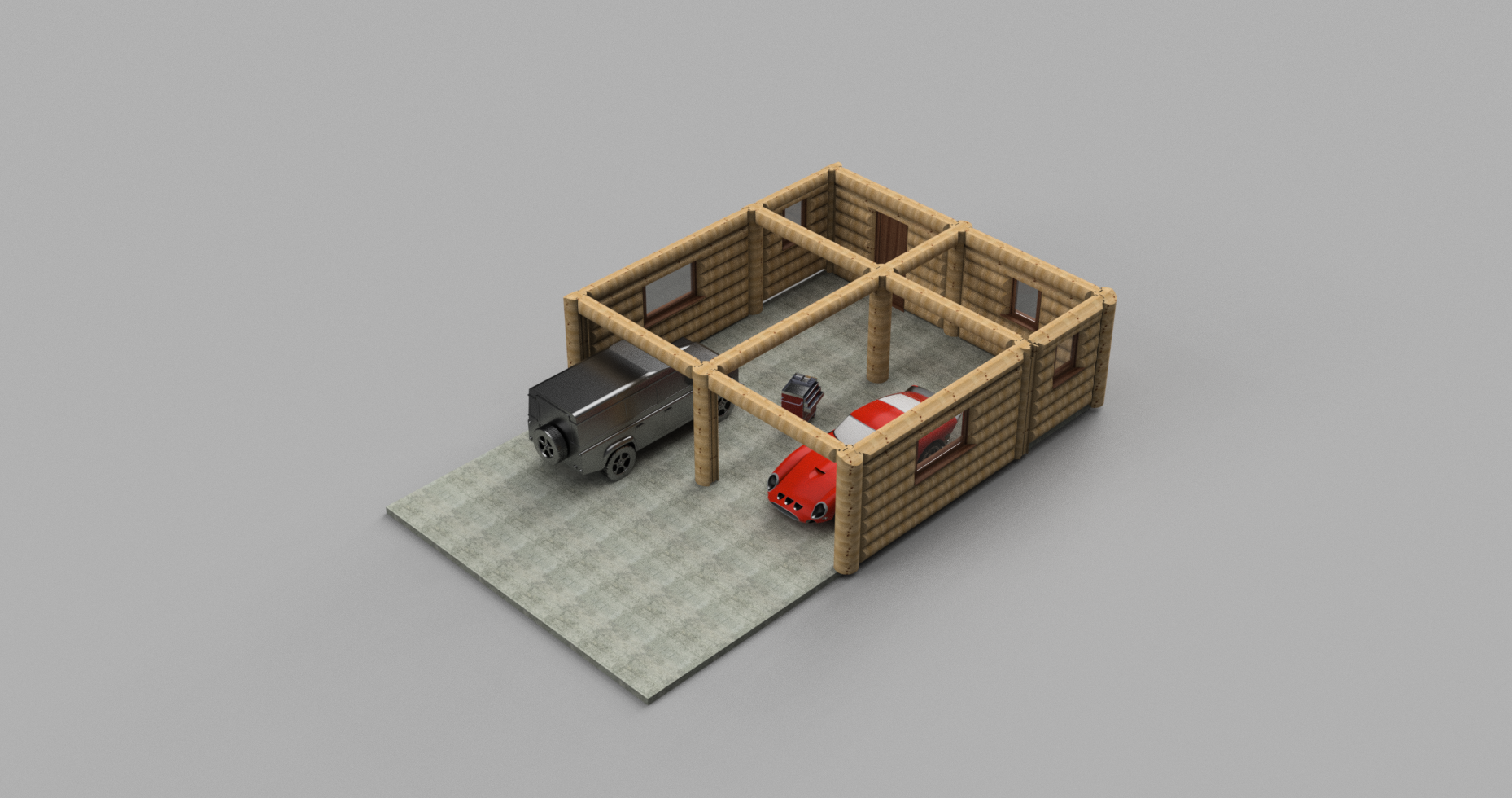

Current setting

Now we start producing with ABB robots. ABB Robots are way cheaper in price - ca. 1/3 of the cost then the huge specialized timber frame machines on the market. They can also cut large beams in any position.

| |

Little space needed

Our setting is ca. 7.5m x 11m = 82.5m2 or 888sq ft. The setting can even be installed outside and run by a generator.

| |

Mobile

This set up is mobile allowing us to produce directly on the building site with a generator. This way we can produce directly from the trailer or on that ground

| |